The SCOR model: definition and tasks explained

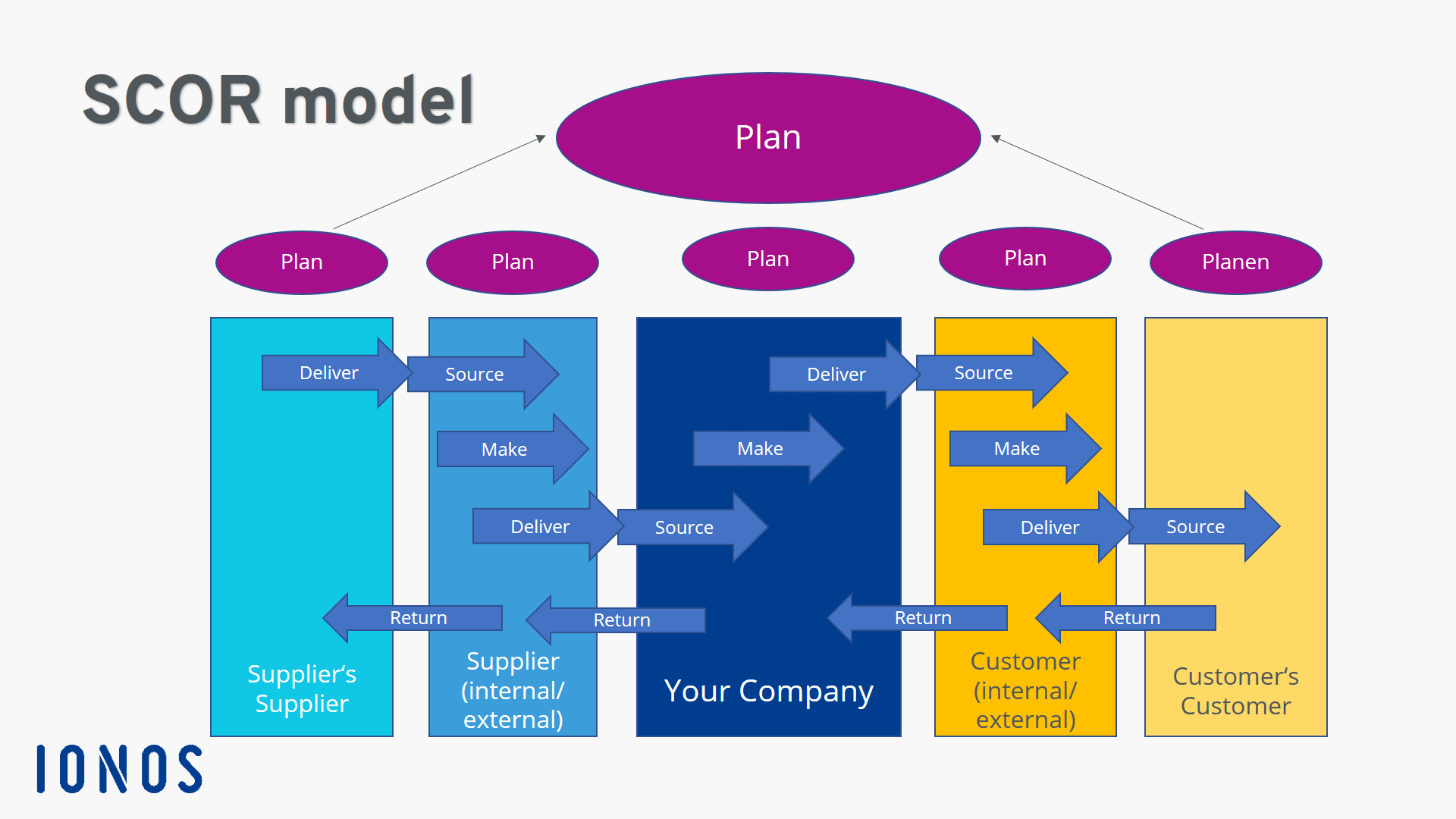

SCOR stands for “supply chain operations reference.” The Supply Chain Council – an independent organisation – defines it as a reference model for analysing, evaluating, and optimising specific processes along the value chain. A supply chain requires permanent overview, adjustment, and improvement in order to keep up the flow of goods from the manufacturer to the customer, and to make structural improvements. The SCOR model was developed for this purpose.

What is a SCOR model?

The SCOR model divides the supply chain into ideal business processes and process categories. This standardised structure enables a cross-company analysis of all information, financial, and product flows within the value chain. Based on data analysis, companies can plan long-, medium-, and short-term, increase the efficiency and effectiveness of their supply chain management, and coordinate and compare the processes between suppliers, manufacturers, and customers.

The first SCOR model was issued by the Supply Chain Council back in 1996. Made up of various companies, the association looks to optimise the value chain. Today, thanks to several adjustments, the SCOR model has become an industry-independent framework for corporate and supply chain decisions. In 2017, APICS (the Association for Operations Management) published the 12th and current version of the SCOR model. Metadata, block chain, and omnichannel are now also integrated as evaluation processes.

SCOR model: layers of business processes

The reference model consists of three levels in hierarchical order. Due to the hierarchical structure of the processes, the supply chain operations reference model can be applied to various sectors and industries. The first and top level of the model (level 1) is made up of five core processes and is considered a strategic level. This is where the organisational core processes take place.

- Plan: Resources are identified, communication, and delivery chains are established, business objectives are aligned with supply and demand, and best practices of the five core processes (plan, source, manufacture, deliver, and return) are examined, taking into account inventory, transportation, regulatory requirements, and resources to improve efficiency.

- Procure (source): The procurement of goods and services taking into account the demand for and availability of goods, purchase, receipt, testing, and provision of raw materials.

- Manufacture: Production planning and manufacturing, quality control, packaging, and demand planning of market-ready products.

- Deliver: Order, transport, warehouse and distribution management, and all processes related to the delivery of completed goods and services.

- Return: Customer service and supplier processes associated with any kind of return and disposal of goods.

The SCOR model’s basic structure was expanded in 2012, adding a further category to its 11th version:

6. Support (enable): Processes related to supply chain management, e.g. business rules, databases, risk management, legal requirements, contractual and business regulations.

SCOR model: configuration layer

The second, tactical level (level 2) divides the model into three process types. This simplified structure is intended to promote the performance of the supply chain independent of its company and industry affiliation. Standardised hierarchies allow performance values to be applied to companies of different sizes and a catalogue of best practices to be designed independently of company specialisation.

The three superordinate process types of the configuration level are:

- Plan: Providing raw materials and setting up planning periods to meet planned and expected demand.

- Execute: Processes that emerge from the planning process and influence product status (e.g., distribution, control, transformation, redirection) depending on real or aggregated demand.

- Enable: All processes that organise and prepare information and services between supply chain partners through analysis and evaluation of planning, and performance data.

SCOR model: design level

The third, operational level (level 3) is called the design level. Here, the processes of the configuration level are broken down once again in greater detail with sub-processes, based on input-output relations.

A performance measurement system evaluates and analyses the process elements (e.g. costs, business planning, capacity checks) and measures the financial success of a company. At the design level, the actual definition of process elements and the first step towards increasing efficiency and supply chain optimisation through the SCOR model takes place.

The four cornerstones of the SCOR model

In addition to the supply chain levels mentioned above, process flows between companies and internal or external partners are also structured into four main pillars. These four pillars define the SCOR model as a reference framework and make it applicable to all sectors. Standardised processes and key figures enable the model to be used for cost/performance optimisation in simple or complex supply chain management operations.

First pillar: process modelling

The first pillar of the SCOR model comprises the five process categories already described (plan, procure, manufacture, deliver, return) and the process types: plan, execute, and enable. The SCOR design, that is, modelling a value chain, introduces standards that enable performance to be described. By categorising and characterising process flows, companies can focus on improving the quality and cost efficiency of manufacturing and delivery.

The reference model of hierarchically ordered process flows enables companies to communicate with their contractors along the supply chain about services, design processes, and performance.

Second pillar: measuring performance

The second pillar in the SCOR model uses a unified system of more than 150 key performance indicators, which are hierarchically structured. KPIs are used for the internal evaluation of performance and the external analysis of the supply chain, and are assigned to each detailed process in the SCOR model. Supply chain management can be split between the enterprise view (internal-facing) and customer view (customer-facing).

From the enterprise view (internal), specific key figures evaluate performance attributes like costs and capital. From the customer's point of view (external), it is necessary to evaluate delivery reliability, responsiveness, and adaptability. Indicators can be used to measure and describe the performance of individual contractors within the supply chain and the performance and efficiency of the entire supply chain.

The evaluation considers factors like performance, costs, and planning/execution time, and allows processes to be compared with best practices and competing supply chain strategies. The hierarchical and multi-dimensional structure of key performance indicators allows processes such as processing time to be linked to performance indicators or service level to punctuality and delivery quantity, with the aim of improving performance.

Third pillar: best practice

The aim of applying the SCOR model is to execute orders in the most efficient way possible. This means achieving a perfect balance between delivery, quantity, punctuality (from the customer's point of view), reliability, and cost efficiency. In order to assess performance at each stage of the supply chain, best practice values are needed as a guide and a benchmark. These best practice values can consist of customer-related, internal, shareholder-related, and cross-company performance values. By comparing them, conclusions on performance can be drawn in the long-, medium-, and short-term.

Fourth pillar: positive effects on business

Following the analysis of performance measurements based on real, targeted, and ideal key performance indicators and performance data, it’s necessary to determine positive effects (e.g. profit, performance increase, and cost reduction), and to standardise processes that led to an increase in performance and include them in value tables. On the other hand, the key figure metrics should enforce cost reduction along the supply chain (material and personnel costs, costs for warehouse and transport logistics, and return costs).

Boosting efficiency with the SCOR model

Implementing a supply chain operations reference model and a KPI system can optimise the following aspects in a value chain:

- Structure and organisation of logistical processes through pre-modelled business processes

- Application of the KPI system at different process levels to align coupled processes and their performance

- Key performance indicator metrics for the creation of best-practice guidelines, which can be used to further increase efficiency

- Identification, implementation, and standardisation of IT solutions and software tools for cross-company communication and process configuration

SCOR model example: benefits in e-commerce

The digital boom of the 1990s linked up national and international industries, and accelerated communication and cooperation along the supply chain through uniform internet protocols such as HTML, HTTPS, and TCP/IP. The digitalisation of business processes and e-commerce reimagined supply chain management from the ground up.

Business is no longer conducted only in local branches. Digital supply chains and online retail platforms are decentralised across the world and no longer rely on physical presence or face-to-face communication. In e-commerce, it’s possible to never meet one's own suppliers, customers, and contract partners in person, as long as supply chain management is well-organised and the SCOR model eliminates weaknesses and closes gaps in the supply chain. Since a large part of the processes are carried out via digital channels anyway and everything is, therefore, already well-documented, data can be easily analysed in e-commerce – and processes can be better optimised.

To set up your own e-business, you need to follow the same planning and implementation steps as when you open a company. Company goals need to be aligned with delivery/transport logistics, distribution channels, capital, supply and demand, and compared with performance measurements.

In e-commerce, applying the SCOR model comes with significant challenges, because online customers have high expectations, including fast delivery, low costs, easy pay methods, available and efficient customer support. If you’re looking for ways to optimise your e-business or your online store, it’s worth applying the SCOR model to your digital supply chain management strategy.

Our e-commerce website builder combines homepage and online store tools in a single place – the perfect way to launch your e-business. Easily reach all social media platforms and expand your reach and customer base.